Ever felt like your machine or equipment is not working the way it used to? Maybe it’s making strange noises, heating up, or not running as smoothly. These little signs are easy to ignore, but they often point to one major issue — worn-out ball bearings.

At High Temp Bearings, we’ve seen how ignoring these early signs can lead to bigger, more expensive breakdowns. That’s why it’s important to know when your ball bearings need replacing—and how to spot the signals early.

The Role of Ball Bearings in Your Machinery

Ball bearings are small but essential parts used in almost every machine — from fans and motors to vehicles and industrial equipment. By minimizing friction, they make movement easier and help carry mechanical loads. Basically, they keep everything rolling without wearing down.

But over time, even the strongest ball bearings start to wear out. Whether it’s due to heat, dust, lack of lubrication, or simply long-term use, they lose their shape and function, leading to mechanical failure if not replaced in time.

Signs That Your Ball Bearings Might Be Failing

Knowing when to replace your ball bearings can save you from costly repairs and downtime. Look out for these common signs that your ball bearings might be failing:

1. Unusual Noises

If you hear grinding, squeaking, or rattling sounds coming from your machine, it could be due to damaged bearings. These sounds happen when the bearing’s surface gets rough or deformed.

2. Increased Vibration

Machines are built to run smoothly. If you feel shaking or vibration more than usual, it’s likely due to wear and tear in the bearing. Worn bearings affect balance, leading to uneven motion of components.

3. Overheating

Excess friction in worn bearings leads to a rise in temperature. If your machine feels hotter than normal, that’s a clear sign something’s not right internally—often, the bearings.

4. Reduced Performance

A drop in speed, power, or responsiveness can mean the bearing is no longer doing its job. Your machine might take longer to start, or not run as efficiently.

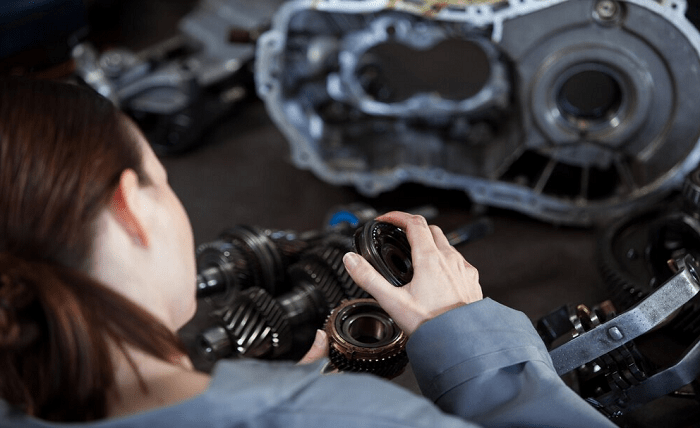

5. Visible Wear or Corrosion

If you’re able to inspect the bearings physically, look for signs like rust, cracks, discoloration, or dirt buildup. These visual cues often mean the bearing is on its last leg.

How to Check for Bearing Problems

Even if your machine isn’t showing big problems yet, regular checks help you catch issues before they grow. Here’s how:

- Listen closely during operation. New noises are usually the first sign something’s wrong.

- Use vibration monitoring tools to detect irregular movements.

- Inspect regularly, especially if your equipment runs continuously.

- Watch for lubricant leaks. Bearings dry out over time and without oil, wear happens faster.

- Check temperature if possible — overheating bearings can damage other parts too.

At High Temp Bearings, we help industries monitor and maintain their bearings before things go south. Preventive care always beats costly repairs.

How Long Do Ball Bearings Last?

This depends on a few things — like load, speed, environment, and maintenance. In perfect conditions, they can last thousands of hours. But in real-world use, they wear faster due to dirt, misalignment, or improper lubrication.

It’s smart to replace them before total failure. Not only will this keep your machine running, but it’ll also save you money and stress.

Why Choose High Temp Bearings?

When it comes to reliable performance, High Temp Bearings delivers more than just parts—we provide long-lasting support. Our team guides you in choosing the right bearings, keeps you in the loop, and offers tailored advice for your machinery.

We specialize in high-temperature applications, where regular bearings don’t survive. If you’re operating in harsh conditions, you need bearings that can handle the heat, pressure, and wear—without constant replacements.

Conclusion

If your equipment is acting up, it might be time to inspect your ball bearings. These small components play a big role in machine health, and spotting early signs of failure can prevent major breakdowns.

At High Temp Bearings, we’re here to help you detect problems early and provide you with the right solutions.

Don’t wait until it’s too late—reach out to High Temp Bearings today and keep your machines running at their best!